Driving the industry forward for over 30 years.

Contact us

| Engineered to work without jams | Reliable solutions that last | 30 years of innovation |

| Our screw feeding and presenting systems are engineered to work non-stop without jams, errors, and with minimal maintenance. | Our products are ideal for manufacturers that need to streamline their production facilities. |

We have been the screw automation industry’s leading experts when it comes to engineering solutions for any and every application – simple or complex. |

20Nm torque capacity

Can adapt to most screwdriver tools

Small size & weight

Simple design with long life

Works well for right-handed

Less than 1.5mm push down

41, 57, and 107mm bit strokes

Standard 89mm bit works most of the time

Easy bit change - unthread jaw assembly to expose bit

A modular approach to automatic screwdriver applications designed for low-payload robotic arm assemblies.

The A10 Series of vibratory bowl feeders is designed to work with micro to small-sized screws, nuts, bolts, and other fastener types.

A heavily customized multi-spindle automatic screwdriver head that offers a high torque, and can be configured with up to 6 screwdrivers spindles. Engineered to suit your industrial screwdriving automation application.

The heavyweight of our multi-spindle screwdriving family, the MultiDrive is capable of 500Nm of torque and up to 18 individual screwdriving spindle attachments!

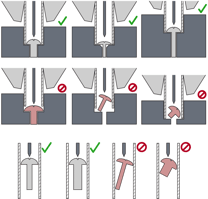

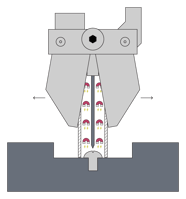

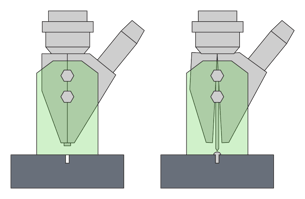

Finder tubes extend from the jaws and the screw freefalls into the screw pocket, followed by the bit.

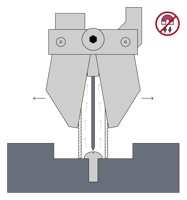

This is the simplest workaround when there is not enough clearance for the drive head jaws to open fully and drive the screw into position.

A magnetic attachment holds the screw to the proper orientation and position while the bit engages and drives.

When the screw’s dimensions and/or the part profile do not allow for a standard finder tube, a magnetic bit extension may be necessary.

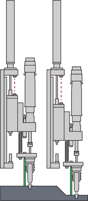

When a screw is non-magnetic, a vacuum suction attachment can work as a substitute for a magnetic bit extend.

The vacuum bit extend uses the same principle as the magnetic bit extend, but instead of relying on magnetism, it uses negative vacuum suction to hold the screw in place

A stand-off heel, typically installed on hand-held devices, prevents part-scruffing by adding a buffer distance between the jaws and the part.

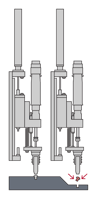

Uses the part’s actual surface as the datum/reference point for driving screws to depth, resulting in consistently driven screws.

The drive head relies on the device’s fixtured location as a reference point for driving screws to depth and does not compensate for deviations.

We advise you in choosing the best material handling team according to your company's processes

Tell us more about your company will be pleased to contact you and talk about a solution for you.